🔗 Cost and Schedule Integration in EVMS: The Backbone of Program Performance

In the world of Earned Value Management Systems (EVMS), one principle separates compliant systems from high-performing ones:

👉 Cost and schedule integration.

It's more than just an EIA-748 guideline—it's the spine that connects technical execution with financial performance. When integration fails, even compliant-looking systems become liabilities. When it works, EVMS becomes the engine that drives mission success.

Across major aerospace, defense, space, and DOE programs, I’ve seen both sides. This article lays out what real integration looks like, where it breaks down, and how to fix it—grounded in lessons learned from the trenches.

🔍 What Integration Actually Means

In a truly integrated system, your:

Planned Value (PV) — formerly BCWS

Earned Value (EV) — formerly BCWP

Actual Cost (AC) — formerly ACWP

...are all structurally and logically tied to your Integrated Master Schedule (IMS).

✅ Each Control Account has corresponding IMS activities

✅ Work Packages are driven by those schedule activities

✅ EV is objectively based on actual schedule progress—not estimates, intuition, or convenience

If EV is entered manually in the cost system without being tied to actual task completion in the IMS, you don’t have integration—you have performance theater.

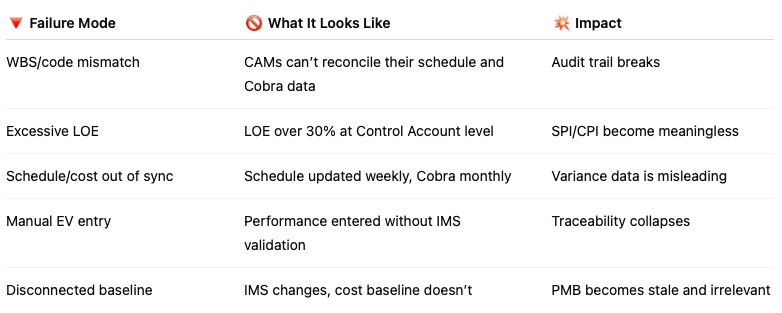

⚠️ Why Integration Fails (Even in “Compliant” Systems)

From billion-dollar primes to smaller emerging players, the failure points are surprisingly common:

Even when EVMS is technically “validated,” these integration gaps expose you to CARs, data distrust, and program overruns.

🛠️ Deltek Cobra: Integration Enabler or Risk Vector?

I’ve implemented Cobra across multiple programs—it’s a powerful engine, but it doesn’t automatically give you integration.

✅ What Cobra does well:

Time-phased cost planning

Robust variance and forecast analysis

Structured Work Package and Control Account management

⚠️ Where integration breaks:

While Cobra supports integration with scheduling tools (Primavera P6, Deltek Open Plan, MS Project) via Integration Wizard, API, or Excel, it doesn’t enforce traceability.

If schedule activity IDs, mapping codes, or milestone logic aren’t actively maintained, Cobra will still import status—but it may no longer reflect real progress.

Performance data can become detached from the IMS, giving a false sense of control.

👉 Cobra will accept whatever it’s fed—discipline is the difference between valid data and misleading metrics.

📘 What EIA-748 Expects (In Plain English)

The EIA-748 guidelines lay out a clear vision for integration:

📌 Guideline 6 – Your IMS must reflect the actual sequence and scope of work, tied to your Control Accounts

📌 Guideline 8 – The PMB must be based on time-phased budgets tied to the schedule

📌 Guideline 10 – Use objective EV techniques—LOE only when unavoidable

📌 Guidelines 22 & 23 – Variance and EAC analysis must tie back to real drivers across cost and schedule

These aren’t theoretical—they show up in every IBR, every surveillance review, and every DOE O 413.3B-based project evaluation.

🧠 What DCMA and DOE PM-30 Reviewers Are Really Looking For

Whether you're preparing for a formal IBR or ongoing surveillance, here’s what the government is watching for:

🔎 Schedule-to-Cost Linkage – Can you trace every Work Package back to IMS activities?

🔎 CAM Ownership – Can your CAMs explain how EV is earned from the schedule?

🔎 Common Cadence – Are IMS and Cobra status updates aligned in timing?

🔎 Baseline Discipline – Are changes to schedule logic or milestones reflected in Cobra’s cost baseline?

They’re not just looking for compliance—they’re looking for credibility. If your schedule says you’re behind but Cobra shows earned value… something’s off, and they’ll dig until they find it.

📈 Best Practices That Actually Work

Here’s what I’ve helped implement in successful programs—and what I recommend every time:

🔷 1. Let the IMS Drive the System

If the schedule isn’t updated, EV shouldn’t move. Period.

🔷 2. Code Activities to Work Packages

Use consistent fields (WP ID, EVT, CA ID) to ensure traceability between IMS and Cobra.

🔷 3. Minimize LOE

Keep LOE under 25–30% and use it only where work cannot be discretely measured.

🔷 4. Status in Sync

IMS and Cobra must be updated in the same cycle. Disconnects = distrust.

🔷 5. Empower Your CAMs

Train them to own both their schedule and their cost performance. If they don’t, your integration is already failing.

🧭 Integration Is a Leadership Standard, Not Just a Technical One

The best EVMS environments I’ve seen—from launch vehicles to nuclear systems—shared one thing in common:

Culture

CAMs weren’t just reviewers—they were owners. Schedule and cost analysts weren’t siloed—they were partners. Integration wasn’t a goal—it was a habit.

In the worst environments? The IMS was a decoration. The numbers were gamed. Nobody trusted the data, and leadership stopped using EVMS altogether.

✅ Final Word

EVMS isn't about the tools—it’s about the linkage. It’s not about checking a box—it’s about protecting your program. And it’s not just about passing an IBR—it’s about owning your baseline.

Cost and schedule integration isn’t a milestone. It’s a mindset.

If you're standing up a new EVMS—or trying to salvage one that's drifting—start here. Start with the truth. And build the kind of system leadership can trust.

👉 Need help integrating your cost and schedule—and building a credible, audit-ready EVMS? At Elixir Value Management Systems, Inc., we help government contractors develop fully integrated EVMS solutions that support mission success and withstand compliance scrutiny.

📞 Let’s Talk!

📧 karlo.menoscal@elixirvms.com

📱 949-351-8896

#EVMS #Aerospace #Defense #Space #ProjectControls #ProjectManagement